RELIABLE EV BATTERY MECHANICAL PARTS SUPPLIER IN ASIA

- Helping industry leaders move forward with advanced manufacturing technology.

- Supporting European clients faster and more flexibly through local supply chain.

- Turning your ideas into precision components with excellent engineering

- DFM support

- Rapid prototyping

- Off-shelf models

- Low volume pilot

- Mass production

Professional evaluation & DFM report

Highly proficient and capable engineering professionals carry out careful review of housing models and tolerance range, and provide DFM report.

Wide range of Portfolio

Rapid prototyping service & Cost efficiency

Board scope of components

Support Service include but not limited to

Meet demand on deferent stages:

R&D lab stage:

off-shelf samples without any tooling expense

Pilot line run: Soft tooling & fast CNC low volume prototypes

Gaga factory mass volume:Competitive tooling cost and short lead time with a daily capacity of 15k per line.

Pilot line run: Soft tooling & fast CNC low volume prototypes

Gaga factory mass volume:Competitive tooling cost and short lead time with a daily capacity of 15k per line.

Validation & Mold Simulation

LET utilizes the

latest technology in engineering and mold flow analysis.

So we can prevent most potential issues in aluminum die

casting production.

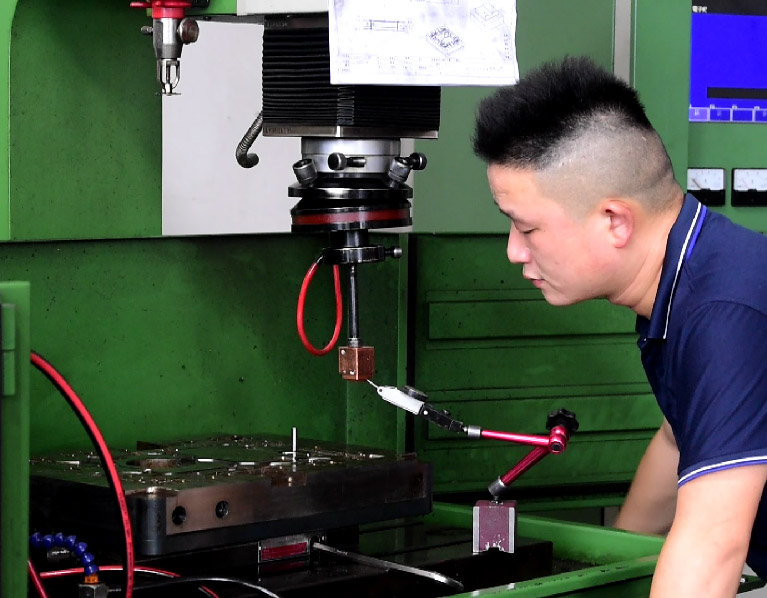

Mold Engineering Team

Experienced aluminum

die casting mold engineers to help you with your

concept visualization, functional analysis, mold flow

analysis, and complete mold design.

In-house Die Casting Mold Fabrication

LET invest our

tooling shop. In this way, we can do the die

casting mold design, mold Fabrication & mold

maintenance In-house.

Complete Mold

Making Equipment

LET equip with

high precision Grinding, Milling, CNC, EDM machines,

etc.

Rapid Tooling Service

Delivering rapid molding

within 2-4 weeks with a fast tooling solution. All the

die

casting tooling and die

casting process can be done in house. This will

help to save a lot process time and make the rapid

tooling service really fast.

Lifetime Guarantee on Mold

By selecting the right mold

steel, proper tooling manufacturing control, and regular

tooling maintenance through die casting production, we

can guarantee tooling life.

Strong R&D Capability

A remarkable engineering

team with over 10 years of professional aluminum die

casting experience enables Sunrise to provide excellent

technical support to customers.

Turnkey Solution

Integrating Rapid

Prototyping, Tooling, Die

Casting, Machining, surface finishing, and

assembly, Sunrise can provide the turnkey solution to

our customers.

Strict Quality Control

Detailed inspections for all

processes with an advanced measurement lab to ensure all

manufactured parts match the client’s high

requirements and international standards.

Wide Range of Al

Alloy

Frequently use aluminum die

casting alloys include ADC12, A380, AlSi9Cu, AlSi10, and

more. Special aluminum die casting alloys can be

requested.

Four Facilities Near Shanghai

Four Facilities near

Shanghai to secure the always on-time delivery to our

clients.

High Mix Low to Medium Projects

As a professional China

aluminum die casting supplier, Sunrise mainly focuses on

the projects with high precision & low to medium

volume.

Comprehensive Collection of Machining

Complete range of machining

with the automation of all procedures: Drilling,

Milling, Turning, Tapping, etc.

Strong Production Capacity

Our machining workshop is

equipped with 23 sets of CNC machining centers, which

allow a wide range of complex processes for top-notch

quality.

High-Quality Assurance

Advanced measurement

instruments to implement accurate and strict quality

control for products’dimension control.

Superior R&D Capability

We are providing unmatched

technical support to our clients on design, drawing

review, DFM, and value-added suggestions to suit project

requirements.

Extensive Production Experience

Rich experience in aluminum

CNC machining, we provide technical support and

produces high precision aluminum parts and for you.

On-Time Delivery

Sunrise is good at the high

mix, low to medium volume aluminum die casting projects.

Complete manufacturing processes in house and proper

management assure on-time delivery to worldwide

customers.

Wide Range of Finishings

LET has in-house

services for cleaning and shot blasting, and also

provides painting, powder coating,

chromate, anodizing, plating, etc. through our partners.

Strict Quality Control

We do careful inspections

from raw material to finished parts. With our premium

test lab, we can meet customer’s high

requirements.

Superior Engineering Capability

The professional and

experienced engineering team in Sunrise provides

excellent technical support for all our customers.

Well-package Design

Specialized engineers to

design product packaging and to test the packaging to

make sure that the parts will be protected well all the

way in transportation.

Attractive Product Appearance

With full-set instruments

and quality control for appearance performance tests.

ROHS & REACH Compliance

All the surface finishing

are ROHS and REACH compliant at Sunrise.

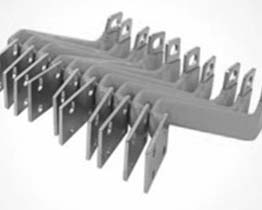

SEE WHAT WE’VE DELIVERED FOR OUR CUSTOMERS

From concept to final product, we’ve helped

customers bring their aluminum parts to life. Here’s a look at some

of the precision components we’ve proudly delivered.

刀片焊接铝壳(双通)

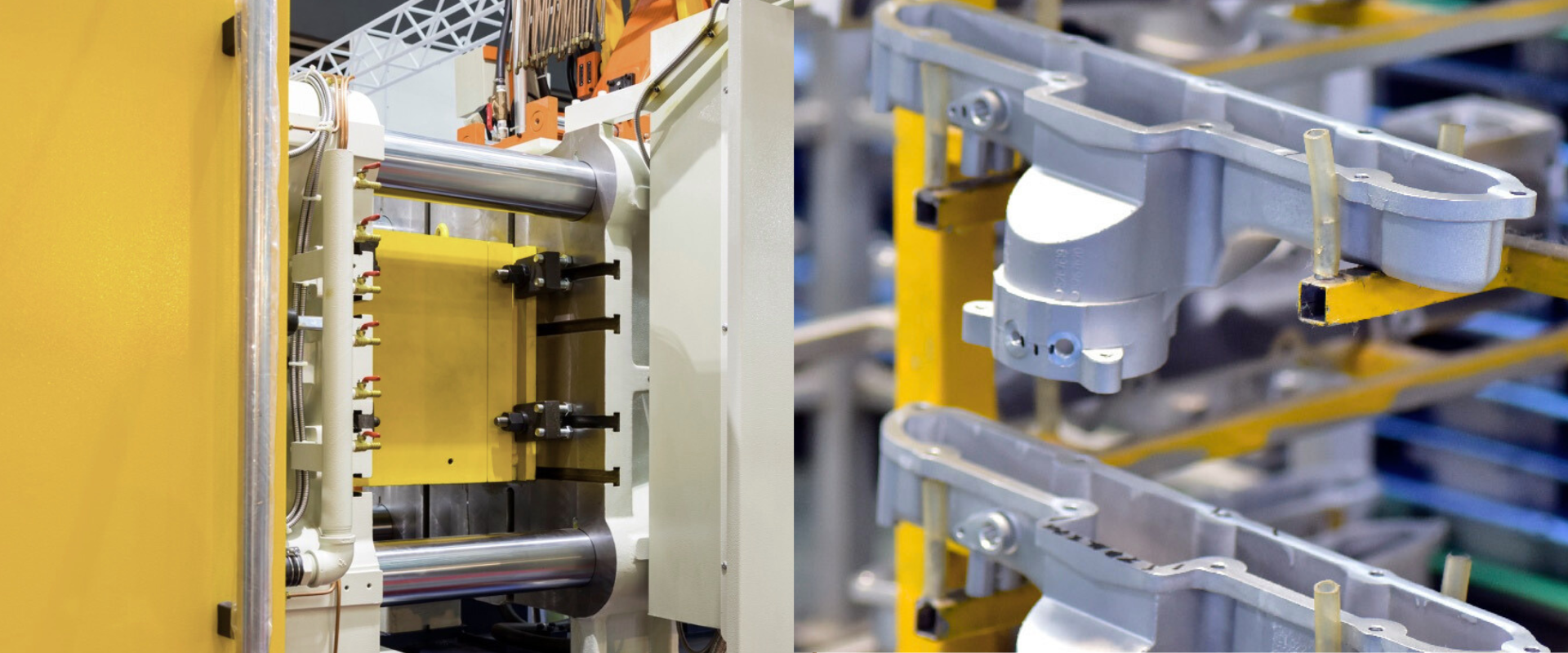

WHERE PRECISION MEETS PRODUCTION

Our facilities are built for accuracy,

consistency, and speed — because your products demand nothing less.

With advanced equipment and a skilled team, we deliver the quality

and reliability your production depends on.

激光切割 Laser Cutting

激光切割 Laser Cutting

折弯 Bending

激光焊接 Laser welding

WHERE QUALITY IS BUILT ON

Quality isn't just a checkpoint — it's part of

every step we take. With advanced measurement systems and strict

inspections, we ensure your parts meet the standards that matter

most to you.

CMM Equipment

顶盖自动组装机

Lid assemble machine

Lid assemble machine

ZEISS CMM

顶盖多功能测试一体机

Multfunctional testing machine

Multfunctional testing machine

Inspection Control

顶盖全自动氦检机

Leaker tester for lid

Leaker tester for lid

X-Ray Test

铝壳口部测试夹具

Inspection fixture for lid opening

Inspection fixture for lid opening

On-site Inspect Control

极柱包胶上下料设备

Terminal Wrapping Loading

Terminal Wrapping Loading

3D Scanning

呼吸测试机

Breath Test Machine

Breath Test Machine

Surface Quality

铝壳耐压测试机

Aluminum Shell Withstand Voltage Testing Equipment

Aluminum Shell Withstand Voltage Testing Equipment

Material Hardness Test

软连接剥胶切割机

Busber tube cutting machine

Busber tube cutting machine

WHAT MAKES LET A TRUSTED PARTNER

We pride ourselves to provide aluminum die casting full services and the added value to our global clients

10+ Years Experience

Sunrise has been dedicated to aluminum die

casting manufacturing for over 10 years of experience.

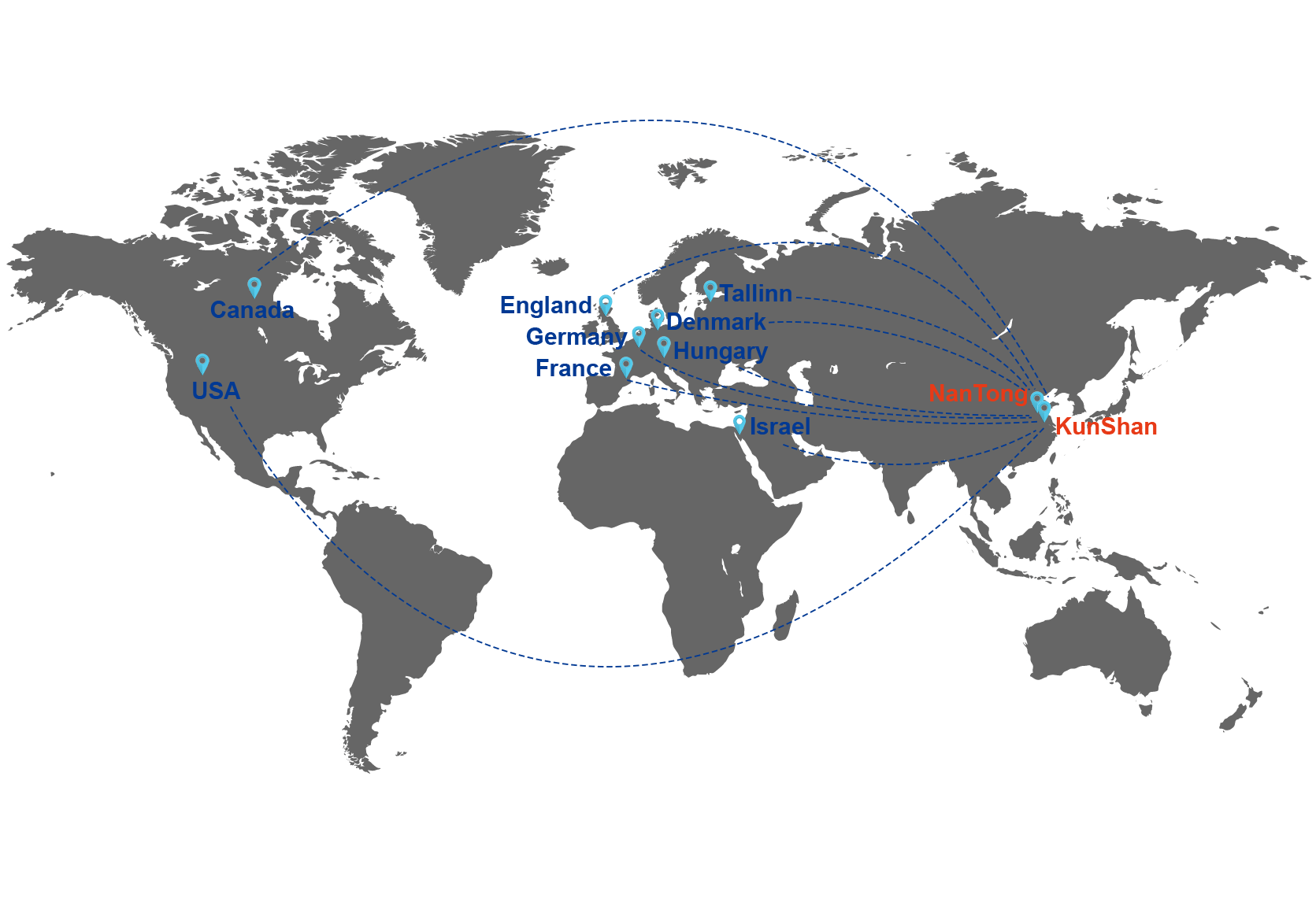

4 Facilities, 182 staff

1 tooling shop in Nantong, 2 die casting

facilities respectively in Kunshan & Nantong. 1 prototyping shop

in Kunshan. A total of 182 staff are here for you.

Advanced Equipment

Sunrise is Equipped with advanced manufacturing

equipment and measurement instruments.

Lean Production

Sunrise always focuses on ensuring quality, while

cutting out waste from design, through production to delivery.

Turnkey Solutions

Offer a one-stop solution to meet you all demands

on aluminum die casting.

Strict Control of Quality System

We keep quality assurance with the process,

technology, material, and method.

Professional Team

Our conscious and thorough teams maintain to

present their professional skill to serve you

On-Time Delivery

Always keep our commitments, and always focus on

on-time delivery.

WHAT OUR CUSTOMERS VALUE MOST

Worldwide customers have acknowledged Sunrise as a

secure and reliable partner in development and production for aluminum

die casting projects. We pride ourselves on our clients’ satisfaction.

SUNRISE & CUSTOMER LOCATION

LET is supplying to over 500 customers

worldwide, mainly in Europe, North America, Asia, and other regions. We

make our customer satisfied wherever they are in the world. We look

forward to serving you soon.

QUICK CONTACT

We Are Ready To Serve Your Projects

HAVE A QUERY?

We’ve mapped out a few answers for you right

away.

WHY SHOULD WE PURCHASE COMPONENTS FROM SUNRISE?

As a professional aluminum die casting

manufacturer, Sunrise has below advantages you may take into

consideration when you choose an aluminum China die casting

supplier.

1. The rich experience engineering team can provide you with professional technical support, manufacturing evaluation, and manufacturing suggestions.

2. Our fast service, typically, can save you 1/2 of standard lead time.

3. One-stop solution service can help you:

a. reduce your workload for supplier management

b. speed up your project time to market.

c. bring you a reasonable cost, good quality, and timely delivery.

1. The rich experience engineering team can provide you with professional technical support, manufacturing evaluation, and manufacturing suggestions.

2. Our fast service, typically, can save you 1/2 of standard lead time.

3. One-stop solution service can help you:

a. reduce your workload for supplier management

b. speed up your project time to market.

c. bring you a reasonable cost, good quality, and timely delivery.

WHAT INDUSTRIES DOES SUNRISE’S COMPANY SERVE?

LET has rich experience in various

industries like Medical devices, Marine electronics, Automotive

components, Telecommunication & Networking, Laboratory

instruments, Aerospace, Smart Metering, etc.

WHAT CERTIFICATIONS DOES SUNRISE HAVE?

Sunrise has the quality certification of ISO9001

& IATF16949 & ISO13485.

HOW DO I REQUEST FOR A QUOTE FROM SUNRISE (RFQ)?

To expedite the quote to your request, please

tell Sunrise the details about your project, please include

the:

a. 2D & 3D Drawings

b. Your project plan or schedule.

c. Required material & surface finishing.

d. Your estimated project life and annual demand.

a. 2D & 3D Drawings

b. Your project plan or schedule.

c. Required material & surface finishing.

d. Your estimated project life and annual demand.

Then Sunrise can evaluate the projects and offer

you the quotations within 3 working days.

WHAT METAL ALLOYS DOES SUNRISE USE FOR DIE CASTINGS ?

Sunrise has the following most popular die

casting alloys in our production:

Aluminum die casting: ADC12 and A380 and AlSI12.

Zinc die casting: Zamak 3 & Zamak 5.

Aluminum die casting: ADC12 and A380 and AlSI12.

Zinc die casting: Zamak 3 & Zamak 5.

WHAT MATERIALS IS SUNRISE USED FOR PROTOTYPING?

Sunrise has materials for prototype

manufacturing as below:

Metal: Aluminum( Al6061 and Al6063 are the most common material), Zinc, Brass, Copper, Stainless steel, etc.

Plastic: ABS, PC, POM, PP, PMMA, Nylon, etc.

Metal: Aluminum( Al6061 and Al6063 are the most common material), Zinc, Brass, Copper, Stainless steel, etc.

Plastic: ABS, PC, POM, PP, PMMA, Nylon, etc.

WHAT IS SUNRISE’S LEAD TIME FOR TOOLING?

Typical lead time is 30~45 days, sometimes over 2

months for large size & complex geometry tooling.

If you need urgently, we can discuss and expedite it.

If you need urgently, we can discuss and expedite it.

WHAT’S SUNRISE’S PRODUCT TYPES?

Sunrise can offer product

prototype, die casting

tooling, CNC precision machining, and aluminum die

casting products.

CAN SUNRISE MAKE VACUUM TOOLING AND VACUUM DIE CASTING?

Yes, Sunrise has a vacuum system and now makes

vacuum die casting parts with this system.

CAN SUNRISE DO LEAKAGE TEST IN HOUSE?

Yes, Sunrise can do both liquid and air leakage

tests in-house.

CAN SUNRISE PROVIDE DFM & PPAP?

Yes, Sunrise can offer DFM ( Design for

Manufacturing ) before tooling fabrication and PPAP documents

before projects going into PSW.

WHAT KIND OF SURFACE FINISHINGS CAN SUNRISE PROVIDE?

We have cleaning and shot blasting in-house. And

through our partner, we can offer various surface treatments

such as painting, powder coating, chromating, anodizing, aluminum

chrome

plating, aluminum nickel

plating, etc.

CAN SUNRISE ACCEPT AND UTILIZE TOOLINGS TRANSFERRED FROM OTHER DIE CASTING SUPPLIERS?

Yes, Sunrise can accept and utilize toolings from

other aluminum die casting companies. But we need to do

physically check on the tooling condition before production.